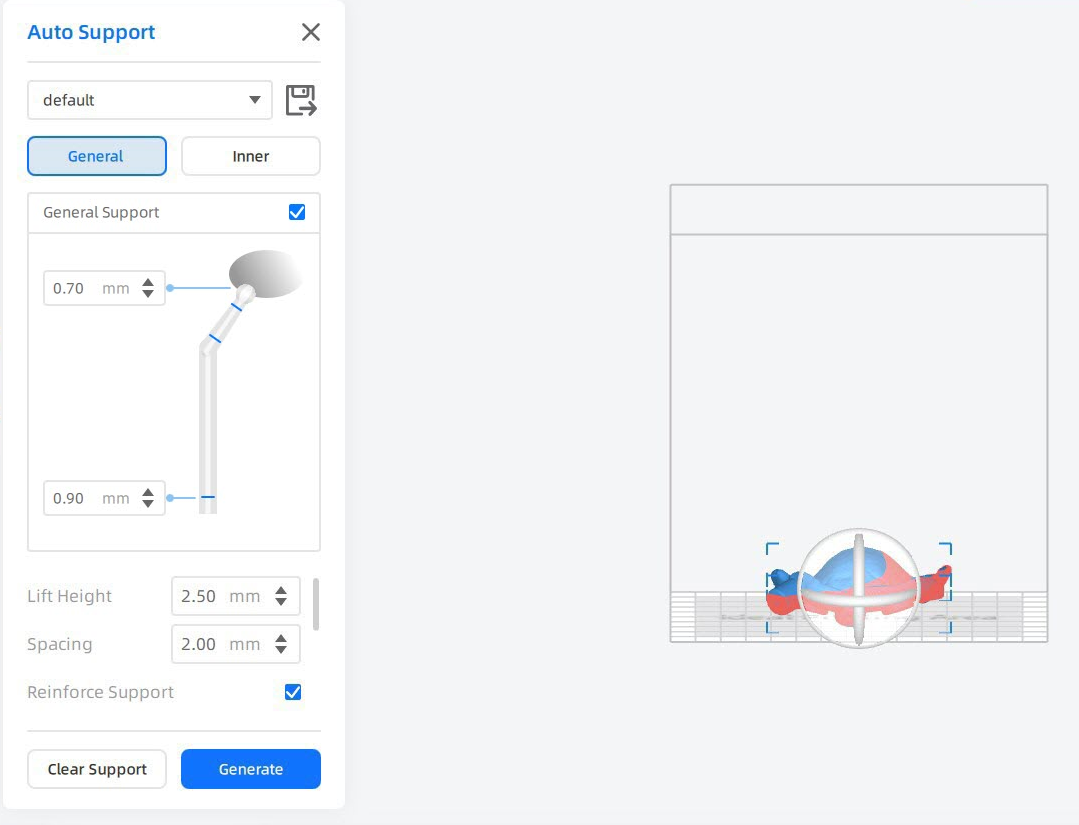

Setting Support Parameters¶

Select the model in need of support, than click  on the Support page and modify parameters to support.

on the Support page and modify parameters to support.

Caution

- Preset parameters on the Auto Support popup default to the ideal way for dental model support settings. Any improper changes may result in print failure.

- Note that gradually increase / decrease parameters by 0.05 mm each time, or the print may fail.

Adjust the Pillar of Support¶

Sometimes the removal of supports might be tricky, in this case, adjusting Support Pillar helps.

|

|

Caution

Ba cautious in adjusting parameters. Aware that the model may fell during printing process when the adherence is too low.

Note

The software optimizes the best support parameters based on the selected printing material that is compatible with the model. You can also choose whether to add regular supports or internal supports by checking ![]() .

.

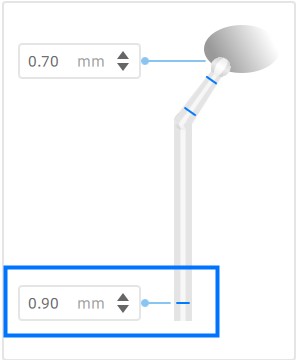

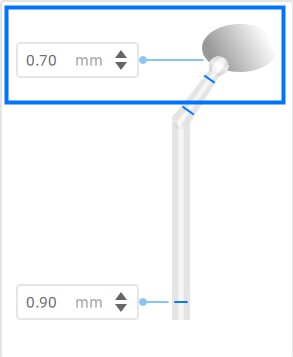

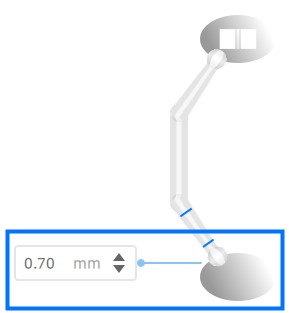

Support Diameters¶

Note

When diameters above increase, the support becomes more stable and the removal becomes harder; when they decrease, the support becomes less adhesive and the removal becomes easier.

Here lists main differences between those diameters.

|

|

|

|---|---|---|

| Common Support Middle Diameter: It reflects the diameter of support pillars. |

Common Support Contact Diameter: It reflects the diameter of the upper contact ball between the model and the support. |

Inner Support Bottom Diameter: It reflects the diameter of the lower contact ball between the model and the support. |

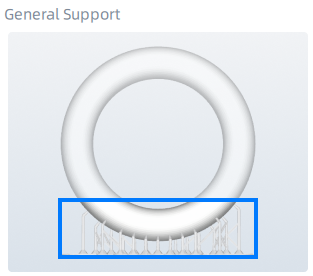

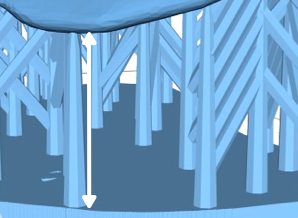

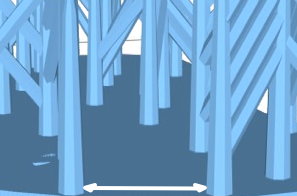

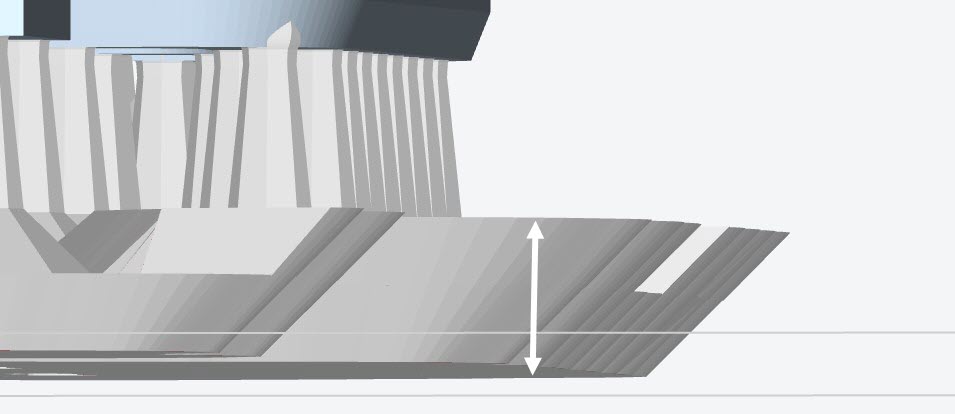

Lift Height and Spacing¶

Note

When the Lift Height or Spacing decrease, the support becomes more stable and the removal becomes harder; when they increases, the support becomes less adhesive and the removal becomes easier.

|

|

|---|---|

| Lift Height: The minimum distance between model and printing platform. |

Spacing: The minimum distance between adjacent support pillars. |

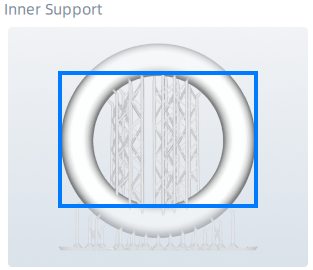

Reinforce Support¶

|

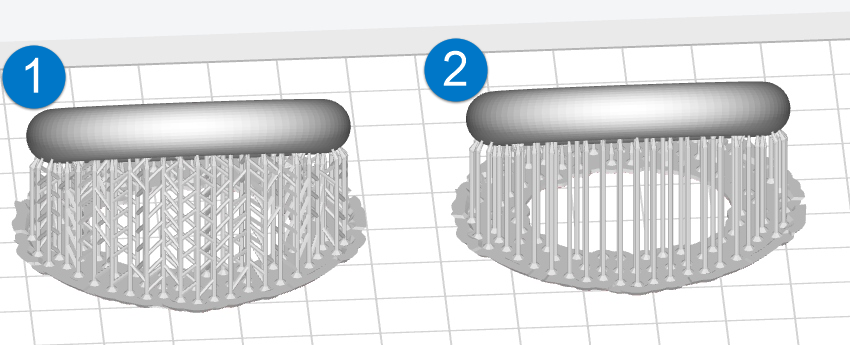

① Reinforce Support: Add tree branch shaped connections between adjacent support pillars. ② Support With no Reinforce: The firmness of support drops significantly. |

It is enabled by default for its strongly improving the strength of support.

Adjust the Base of Support¶

Base Type¶

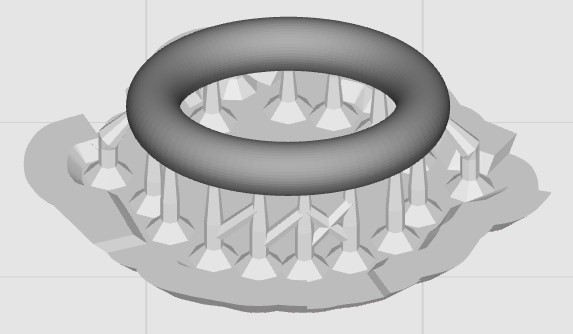

Projection Base is set as the default base type, however, you may replace it with the one more adapting to the application.

There are 4 base types provided for selection:

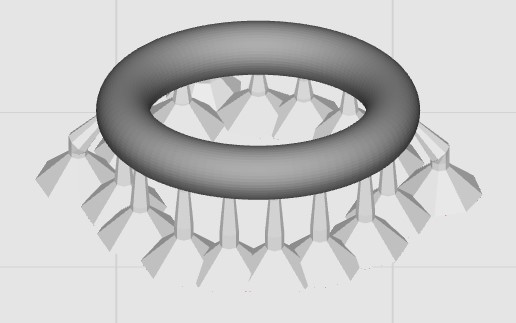

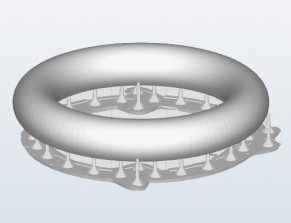

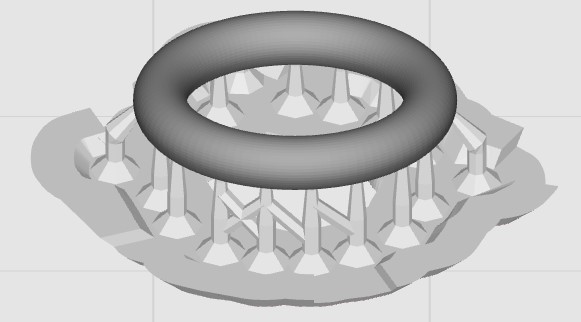

The layers adhering on the platform are pieces of supports. |

Road supports are mainly used to add support to the external edges, while internal areas do not require additional support points. They are commonly used for retaining structures. |

The base achieves the balance between material consumption and adhesion by covering the platform with the piece which expands the contact area. |

The base covers the platform with the out contour shaped piece. |

Base Height¶

|

It is the thickness of the base. When the thickness is proper, it can be easier to remove prints by the cocked edge of the base. |

Base Only¶

After checking this option, the printing model cling to the printing platform only with a base. This function is turned off by default.

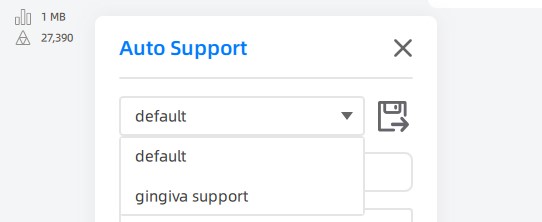

Save Support Parameters¶

|

You can click Generate to preview customized support. When capturing a satisfied preview, click To call out a support parameter profile saved previously, click |