Calibration¶

With calibration, the scanner parameters are recalculated, which not only ensures the accuracy of the scanner, but also improve the quality of scanning.

Note

Calibration is required under the following conditions:

-

When the scanner is used for the first time.

-

The scanner was severely shaken or shocked, such as shocked during transportation.

-

Severe accuracy reduction, such as frequent errors in alignment or unrecognized markers.

-

Incomplete data is acquired during the scanning or serious deterioration of the quality of scanned data.

Warning

-

The calibration board is matched to the device. Doing the calibration with an wrong calibration board will fail to generate good scan data or optimum accuracy.

-

Always make sure that both sides of the calibration board are clean and free of scratches.

-

Do not place heavy objects or sundries on the calibration board.

-

Keep the calibration board away from corrosives, metals and sharp objects to avoid corrosion or damage.

-

It is not recommended to wipe the calibration board. When cleaning the board becomes very necessary, gently wipe it with a piece of a clean damp cloth. Do not use a cloth with chemicals or alcohols to wipe the calibration board.

-

After using the calibration board, put it safely in a box or flannel bag.

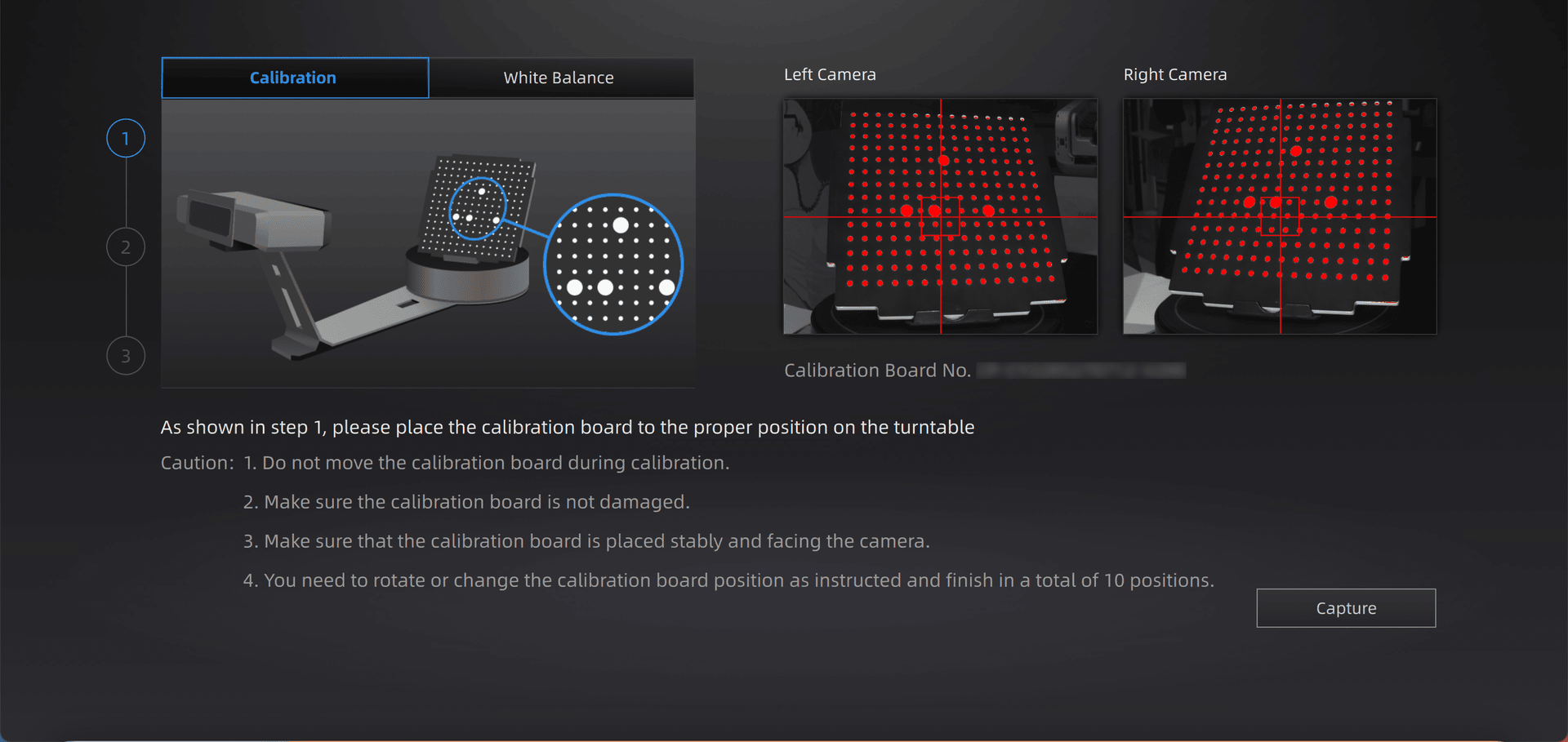

Interface¶

Steps¶

- Place the calibration board to the proper position on the turntable, facing the 3D scanner.

- Follow the prompts on the screen to position the calibration board, ensuring that the center crosshair is aligned with the calibration board in both the left and right camera views.

- Click Capture to start the calibration process. Please don't move the calibration board during the capture.

- After capturing from the current direction, rotate the calibration board in the way shown on the screen.

Note

-

If the calibration fails, please try it again from step 1.

-

If you cannot get the pass result anyway, please contact your supplier or our support team.